Developing high-performance engines has been the backbone of Cosworth since the company’s inception

Whether on land, sea or air hybridisation forms an important part of our electrification offering.

Our state-of-the-art manufacturing facility at Silverstone is ISO 9001 certified

Our Catalytic Generator, is a 35Kw zero emission capable, compact, and lightweight generator

Electrification is now a key pillar of the propulsion industry. We are excited to be playing a leadi

We are a crucial part of wind tunnel development for Formula 1 teams and OEMs

Embark on a journey with Cosworth’s AliveDrive. A versatile ecosystem carefully designed to facilita

From ground-breaking piston technology to bespoke hybrid systems

We strive to deliver diverse, efficient solutions, from ICEs to electric powertrains

We have a range of propulsion and control solutions from ICE to EV powertrains

With our engineering excellence we can offer some of the most efficient, high-performance solutions

Cosworth’s DNA was born from motorsport

Today, we produce some of the most advanced electronics for teams and championships across the globe

With our extensive capabilities, we possess the ability to develop all subsystems of a vehicle

As part of our total race electronics our support engineers are on hand to help troubleshoot

Cosworth service product returns

The Antares range of ECUs are highly-developed control platforms featuring multiple FPGAs and proces

We are continually developing our offerings across the board

Nurturing young engineering talent is a core part of Cosworth’s values

We’re on the search for the brightest minds that can solve problems and are up for a challenge

Interested in working with us?

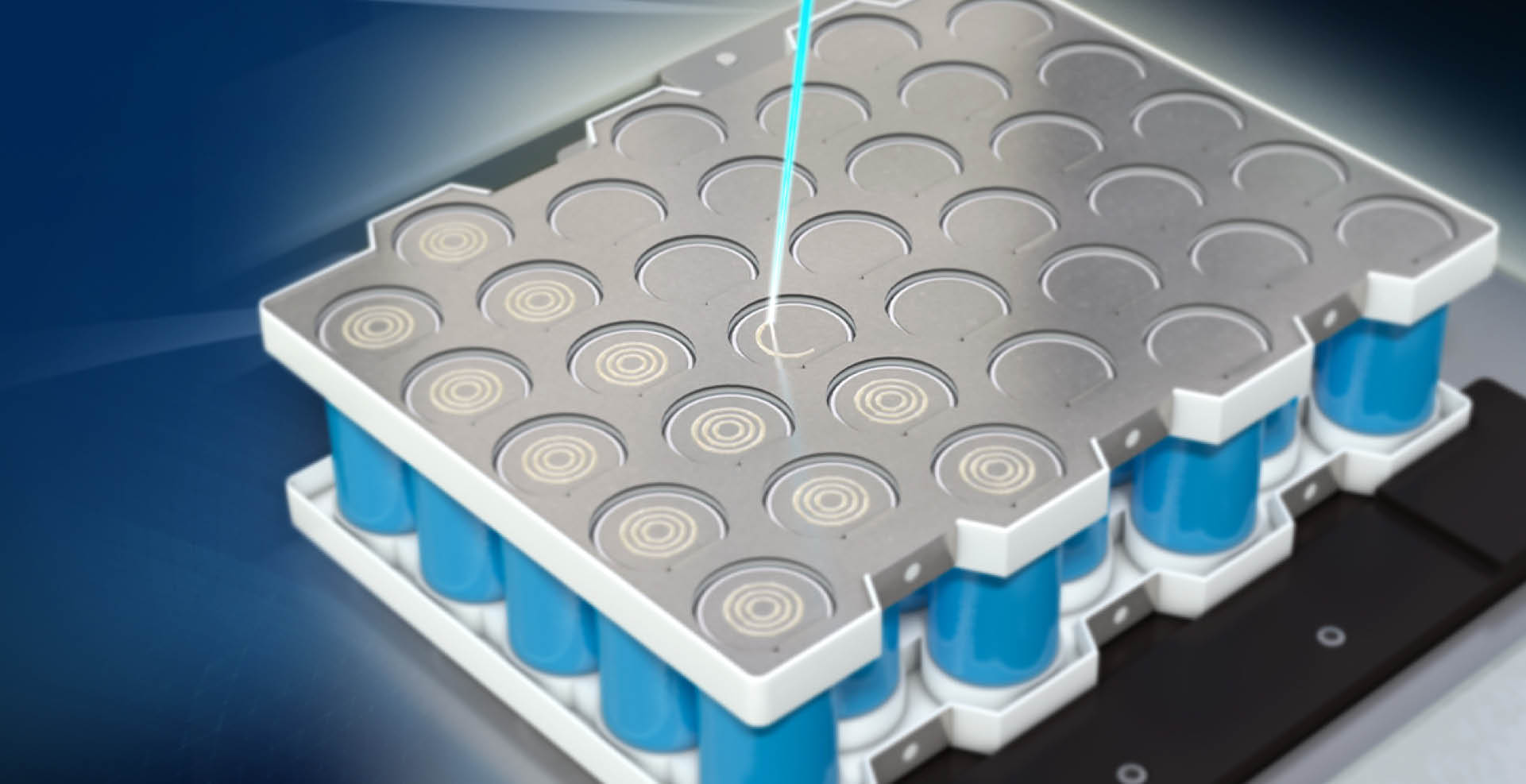

Cosworth has joined forces with Cambridge Vacuum Engineering (CVE) and TWI to design, build and test an electron beam welding machine that hopes to optimise the manufacturing of battery packs.

Cosworth has joined forces with Cambridge Vacuum Engineering (CVE) and TWI to design, build and test an electron beam welding machine that hopes to optimise the manufacturing of battery packs.

The EB-Bat project will be funded by Innovate UK, under the Faraday Battery Challenge. The Faraday Battery Challenge is a partnership between Innovate UK, UK Battery Industrialisation Centre, and The Faraday Institution to support the research and development of the most promising, innovative, and sustainable battery technologies for the propulsion of electric vehicles in the automotive sector. £27.6 million of funding is being invested across 17 research and innovation projects and facilities that will drive the growth of a strong battery business in the UK.

The use of electron beam welding is set to be 20 times faster than laser welding, and is not impacted by the reflectivity from copper and aluminium, allowing for more reliable and consistent welds. Other benefits of electron beam welding include energy savings, a smaller factory footprint, a reduction in scrap material and welding fume control.

The EB-Bat project will provide a compelling demonstration of the process performance, productivity, quality, and economics to the automotive manufacturing sector with an aim to secure funding to take it into production.

The project partners bring together a wealth of experience in the automotive industry, with TWI as a world-leading welding and materials development organisation and CVE, designers and manufacturers of electron beam and laser welding machines for many applications, including turbochargers.

Developing and manufacturing flexible battery solutions is one of Cosworth’s core capabilities, the Cylindrical Scalable Modules is a prime example of this. The electron beam welding offers a more efficient and reliable way to manufacture batteries, maximising the battery technology’s potential and the new manufacturing techniques can be transferred across the wider Cosworth Group.

Cosworth empowers organisations to reach their full potential with innovative solutions and world-class products and services that enhance performance and enable greatness.

The Octagon, St James Mill Road

Northampton, NN5 5RA, UK

Brookfield Technology Centre,

Twentypence Road, Cottenham,

Cambridge, CB24 8PS, UK

5355 W 86th St,

Indianapolis, IN,

46268, USA

Unit 9, Silverstone Technology Park

Silverstone Circuit,

Northants, NN12 8GX, UK