The future of the propulsion industry needs to be powered by a diverse array of energy sources.

Overview

We recognise the role we play in tackling current environmental issues; our work in delivering emissions compliant propulsion solutions is a case in point, but it doesn’t stop there. We are committed to solving the bigger industry challenge of how we stop using fossil fuels all together.

Of course, there are already a variety of solutions on the market: hybrids and fully electric vehicles, while hydrogen-power is also being harnessed. However, none of these solutions is ready to replace fossil fuel power completely.

EVs still suffer the plague of needing time to charge and give drivers range anxiety, while current hybrids, by nature, still use fossil fuels to provide some of the power. Hydrogen used as a fuel to generate electricity needs to be extremely clean, so much so that the energy used to produce, transport, and contain it reduces its efficiency as a fuel to levels close to that of ICEs.

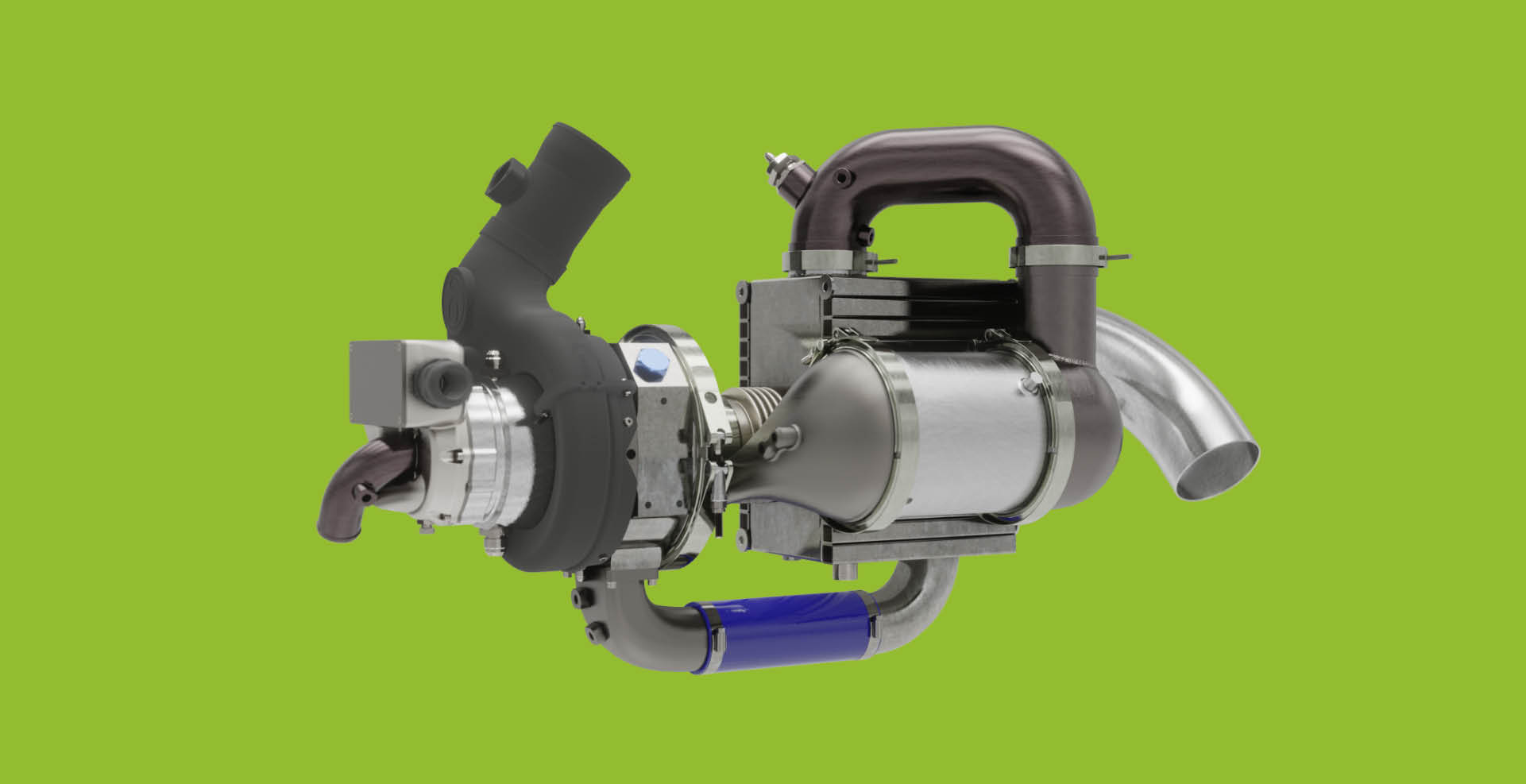

Clearly, we need to develop a solution to fill the void between our current energy sources and a fully sustainable future. This is where our EV specialists, Delta Cosworth, supports our broader corporate vision with the catalytic generator, or ‘Cat Gen’ as it’s known: an innovative, small, lightweight, extremely low emission, turbine derived generator based around readily available components and materials.

Challenges

Considering the vast scale of what needs to be undertaken – developing a solution that literally accelerates the process to end the use of fossil fuels entirely by almost a decade – there were obviously going to be many challenges.

Firstly, this new technology needed to be cheap, simple, and reliable, since the product must be usable across a wide array of vehicles. An expensive solution would prohibit it from being economically viable for use in the majority of cars and also heavier vehicles, such as trucks or buses. Equally, simplicity is key to allow it to be reliable, easy and cheap to service and, finally, able to fit into a wide range of applications.

The device also had to be capable enough of sustaining an infinitely long journey at reasonable speed. In simple terms, drag squares with speed so to go one unit faster, roughly double the energy is required to get it there; high speeds sustained for long periods of time are highly energy intensive. Our solution had to take this into account.

With the current solutions on the market, and the current trends around energy efficient alternatives, we needed to develop a product that could tie into the already existing ecosystem of batteries, motors, and energy sources. We needed to produce a solution that would generate electrical power to extend the vehicle’s range to make the best use of the highly efficient electric drive motors.

Piston engines are complicated, slow, and difficult to control when it comes to managing emissions. They typically run between 2,000-3,000°C, which is above the minimum temperature at which harmful NOx gases are produced, resulting in the need for expensive aftertreatment components that also add weight.

Another big challenge when deciding how to approach this void in the propulsion market was how to futureproof the solution. The EV market may still be in its infancy, however there are already some strong trends when it comes to the solutions being developed. To make our solution viable, we needed to produce something that would still be relevant and useful even when we do move away from fossil fuels. Additionally, the current legislative climate around electric vehicles is changing year on year. How do we ensure the technology we develop meets the government requirements of the future?

Once we had opted to go down the route of developing our catalytic generator we were met with yet more challenges.

Turbine technology is quite understated. It has become mainstream within the power generation sector but is not commonplace in the propulsion industry and is very new when it comes to our planned application, recharging batteries whilst in motion. Developing a unit poses new packaging challenges.

Lastly, we tackled the versatility issues. The future of the propulsion industry needs to be powered by a diverse array of energy sources. Historically we have relied on one source, fossil fuel in its various forms. In the late 19th century, when powered transportation was in its infancy we relied on coal, largely to produce steam. This powered trucks, trains, and sea vessels. Moving into the 20th century we progressed onto oil in various forms such as diesel, petrol and kerosene, far more energy dense than coal, these fuels enabled us to produce smaller more efficient powertrains and vehicles. Oil also paved the way to aerospace industry we rely on today. With this knowledge we understand that the most effective solution will be useful for the entirety of the transportation industry. It must work in the smallest of passenger cars scaling up to large trucks, sea vessels and in some cases provide the power to sustain flight. The solution must also be able to use different sources of energy, removing the current constraints of relying on one source.

The marine industry is pushing to reduce emissions around ports and harbours. The issue stems from diesel engine boats idling around these areas for long periods of time, burning large quantities of diesel for a relatively small amount of work. Stop-starting and idling are the most inefficient conditions in which to operate; combustion engines are most efficient at steady, optimised engine speeds and loads. However, the nature of moving around a port is anything but steady. Engines are changing speeds continuously, greatly increasing the emissions of these vehicles.

We believe the way in which we use our Cat Gen can greatly benefit movements around ports and harbours for a variety of reasons, first among these is the fact that no matter what the vehicle does, the Cat Gen will either be off or running at an optimised speed and load due to the fact it is not directly connected to the drive motor, instead a battery is acting as a damper for the motor’s varying power requirements. With the range of vehicles that require powering, scale is a question that comes to mind. How could we provide a solution that could fit into a small passenger car, but that could also be scaled up or powerful enough to provide enough energy for large trucks, heavy military vehicles, boats and even planes? Our engineers found solutions for this very conundrum.

Solutions

Our Cat Gen has undergone five years of development, from initial concepts through to multiple prototypes and test vehicles.

We have taken microturbine technology and used it as a range extender for BEVs (Battery Electric Vehicles). The benefits of developing a microturbine are that it is a steady state machine, meaning that the turbine runs at a specific speed no matter what the vehicle may be doing. This allows us to control the reaction process extremely accurately, minimising the emissions of our unit to negligible levels.

The reaction process is not traditional combustion; instead, we chose to react the air and fuel across a catalyst, allowing a thermal reaction process to take place at a slower rate than a piston engine and at a much lower comparative temperature. We see temperatures of 1,000°C which is crucially below the point of harmful NOx production. The catalyst is also used for the start-up, giving us complete control of hydrocarbon emissions during all running conditions.

The thermal reaction process requires heat to allow the reaction to take place. This becomes an issue during the start-up phase. We got around this by electrically heating the catalyst for a brief period of time before fuel and air are passed through it. This pivotal development enables the Cat Gen to be a viable solution for the propulsion of vehicles, as quick start-up is a key requirement for the majority of the transport industry.

Selecting the microturbine path allowed us to develop a cost-effective solution to address the emissions and range issues. Firstly, microturbines run at incredibly high speeds allowing us to reduce the size of the unit. High output speeds require much less torque than a traditional generator to produce the power required for transportation vehicles.

By building the Cat Gen with parts and materials that are already widely in circulation we have considerably cut the costs of developing such a device. Sizing it the way we have has also reduced the need for the most expensive components materials, further reducing costs and benefiting the environment. For example, we balance the size of catalyst to ensure that the reaction takes place fully but small enough to conserve the precious metals that we must use to produce this component. There is also no need for aftertreatment which is how traditional piston engines deal with emissions, avoiding additional cost and weight.

We pair the Cat Gen with a battery pack meaning that it never provides energy directly to the motors. This allows the Cat Gen to work (on average) between 5 and 10% of journey times, greatly reducing emissions further. The battery pack is smaller than that of a tradition EV, crucially however, utilising a range extender to bolster the batteries, range becomes infinite, and the battery size is reduced saving weight, cost and opening up more packaging options.

We are tying the EV development and hydrogen fuel cell technologies together, with the Cat Gen being fuel agnostic. Hydrogen reacts with air in the Cat Gen to generate electricity, producing zero harmful emissions and like fuel cell vehicles the only by-product is water. Where the Cat Gen really stands out is that it doesn’t need the purest H2 to run meaning that sourcing hydrogen can become easier than the current energy heavy process that fuel cell vehicles currently require, making the Cat Gen one of the best, most energy efficient hydrogen devices currently on the market.

EVs suffer when the scale of vehicle increases. Batteries have a relatively low energy density so, as the mass of the vehicle increases, the size of battery required to supply enough energy to move it a viable distance needs to increase drastically. Our Cat Gen produces 35kW of constant power. We deliberately chose this level of energy supply to maximise efficiency, weight, and packaging.

35kW is the best size to showcase this technology for most markets as our units can fit in some of the smallest vehicles such as small city cars, are light enough to fit into weight critical applications such as marine vessels and aircraft. We can also pair up our generators for use in larger vehicles that require more power.

We have demonstrated the benefits of our technology by integrating our Cat Gen into a Ford Transit Custom PHEV hybrid van. We have replaced both the ICE and battery pack with our products. The results are impressive. Not only have we made weight savings, but we have also increased the vehicles range, allowing the vehicle to carry a larger payload and go further before refuelling is required, saving both time and money for logistics companies for example.

The applications for Cat Gen are almost endless from small cars to heavy trucks. Yachts are also now able to move towards electric powertrains with the use of a microturbine, where large conventional 35kW generators are impractical energy sources for the occasions when the air is still. The tiny size and weight of the Cat Gen allow it to sit in a racing yacht for a negligible addition to weight.

It is well suited to military applications too, where vehicles are often out in the field for indefinite periods of time and recharging in a stationary position can be extremely dangerous. Being fuel agnostic is beneficial in these applications too, enabling vehicles to use different fuels when fuel type is not guaranteed in remote locations. Even the aerospace business can benefit from our technology, where battery powered flight for larger airframes is currently not viable.

This advantage of being fuel agnostic futureproofs the device. Currently the Cat Gen uses the available fuels on the market to push electrification further whilst we wait for the development of alternative fuels to become mainstream. Once we get these alternative fuels (be it hydrogen or synthetics or anything else for that matter), the Cat Gen will be able to run on them as long as they’re in a liquid or gaseous state. This safeguards the technology and its place in the industry as a solution for the foreseeable future across multiple markets. With this device we are effectively accelerating the electrification process by enabling battery technology to be implemented into applications the industry has previously not managed.